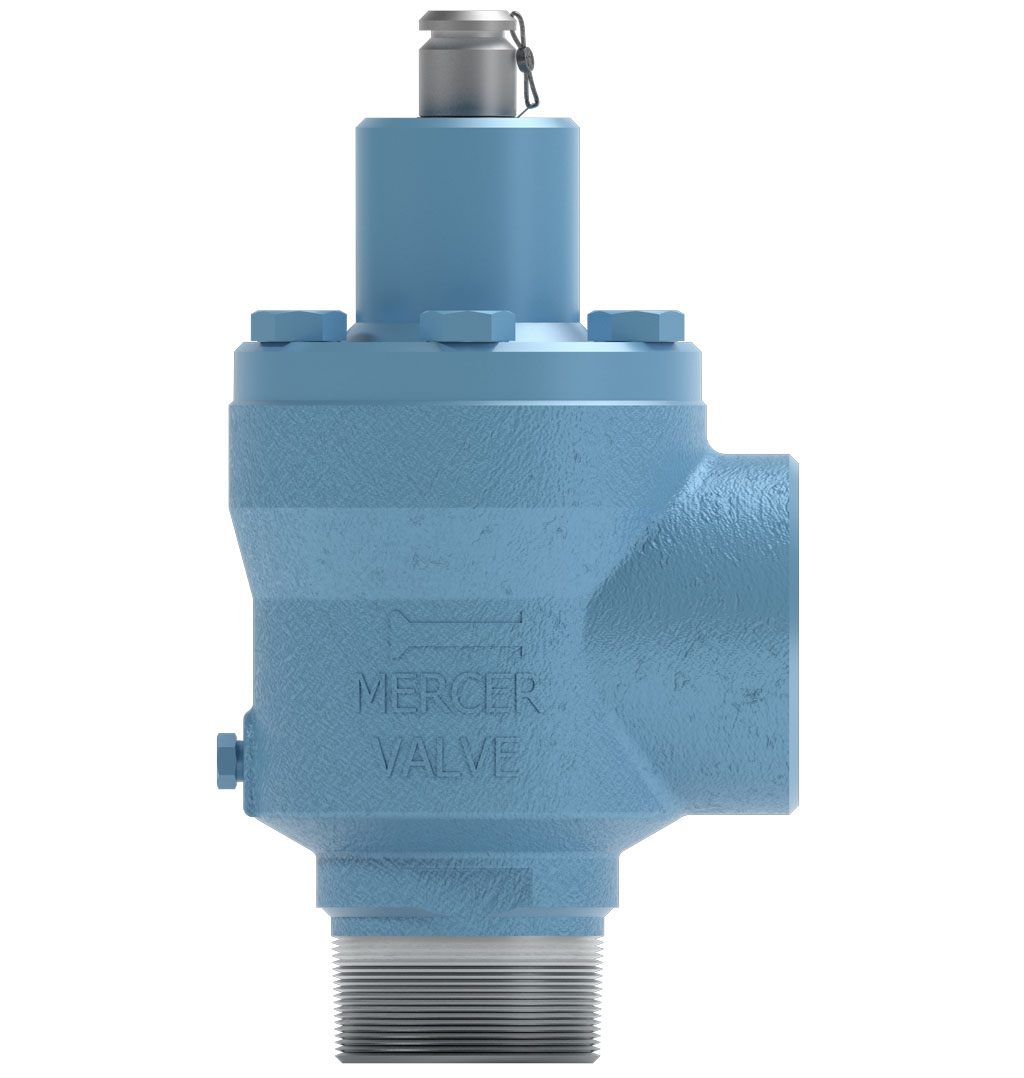

think…mercer first®

Features:

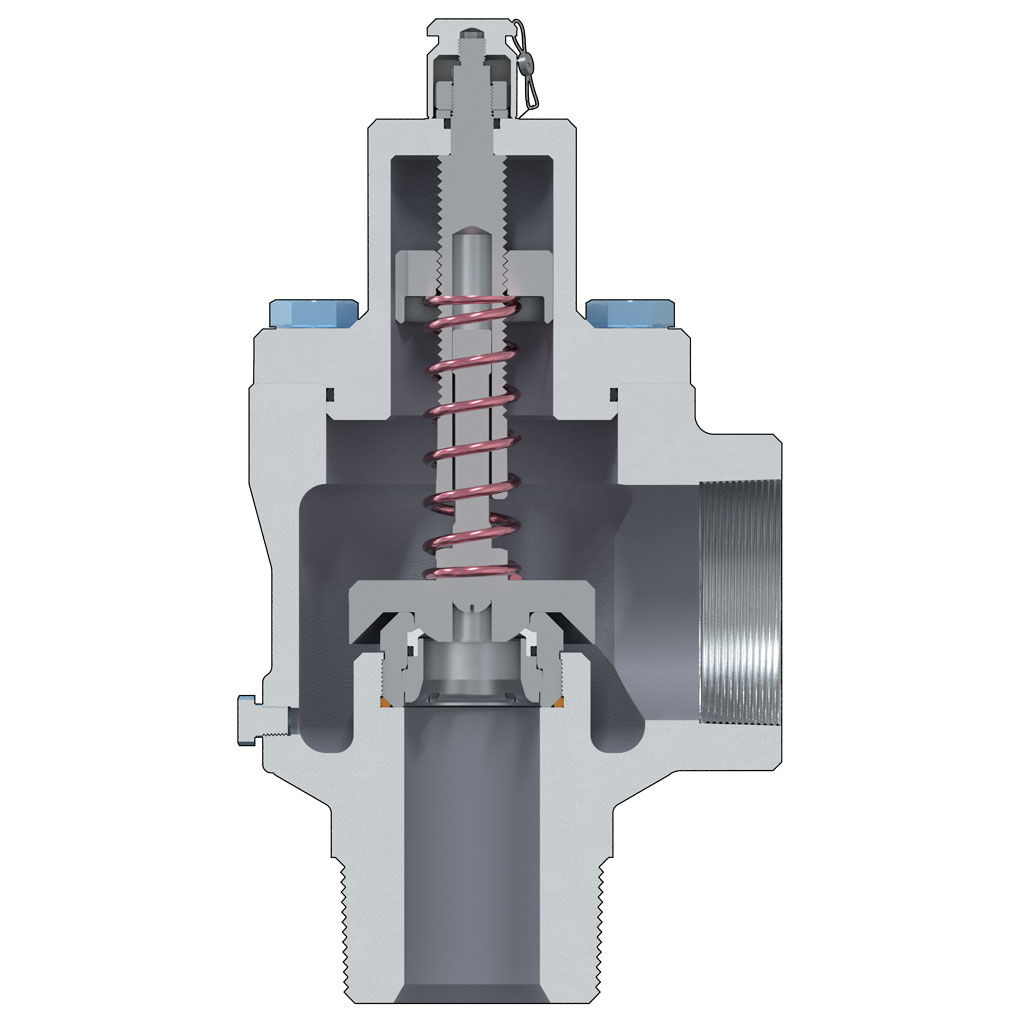

- Designed with "Auto Seat Technology"®

- A low rated and fully guided spring allows for more consistent Set Pressures from pop to pop.

- Consistent Set Pressures allows for repeatable use without the need for excessive repairs or resetting.

- Open, Close, Seat and Seal™

- Fully guided disk for the proper alignment, opening and closing, and reseating of the valve.

- Mechanical Stop prevents wear on parts and controls valve lift.

- Pop Action relief allows the valve to go to full lift at Set Pressure. This helps with DOT regulated applications.

- Non-rising stems allowing valves to be installed in small areas.

- Sour Service Trim available.

- Additional options available to meet NACE MR0175 requirements.

- Canadian Registration Number (CRN)

- Additional options available to meet Conformité Européenne (CE) to PED Directive 2014/68/EU and/or ATEX Directive 2014/34/EU

| Orifice | K (USC) | K (SI) |

|---|---|---|

| OrificeStandard Inlet Size | K (USC)3" | K (SI)DN 80 |

| OrificeInlet and Outlet Connection Types Available | K (USC)Male NPT x Female NPT or Female NPT x Female NPT | K (SI)Male NPT x Female NPT or Female NPT x Female NPT |

| OrificeActual Orifice Diameter | K (USC)1.625 in | K (SI)41.3 mm |

| OrificeActual Orifice Area | K (USC)2.074 in2 | K (SI)1338.1 mm2 |

| OrificeAPI Orifice Area | K (USC)1.838 in2 | K (SI)1185.8 mm2 |

| OrificePressure Range | K (USC)15 – 750 psig | K (SI)104 – 5171 kPa |

| OrificeStandard Temperature Range | K (USC)-20°F to 400°F | K (SI)-29°C to 204°C |

| OrificeASME Flow Coefficient Kd (Gas) | K (USC)0.818 | K (SI)0.818 |

| OrificeASME Flow Coefficient Kd (Liquid) | K (USC)0.707 | K (SI)0.707 |

Mercer Valve Co., Inc. reserves the right to change product designs and specifications without notice.

9100 Threaded "K" | Part Number Selection

91 -

61

A

K

B

5

C

1

D

T

E

84

F

U

G

1

H

I

A | INLET & OUTLET COMBINATION

(See Dimensions & Weights, below.)

B | API ORIFICE LETTER

K – 2.074 in²

C | INLET BASE & BODY MATERIAL

5★ – CARBON STEEL / WCB CARBON STEEL

7 – 316 STAINLESS STEEL / CF3M STAINLESS STEEL

R – 316 STAINLESS STEEL / LCC CARBON STEEL

D | CAP TYPE

1★ – CLOSED CAP

2 – OPEN LIFT LEVER

3 – CLOSED LIFT LEVER

E | SEAT MATERIAL

V★ – FKM

T★ – PTFE

B – BUNA-N

E – EPDM

N – NEOPRENE

Y – VESPEL®

F – FKM (LOW TEMP)

F | SPRING CODE

(Spring codes assigned by Mercer Valve.)

G | TRIM CODES

U★ – 316 S.S. DISK & NOZZLE (GAS SERVICE)

L★ – 316 S.S. DISK & NOZZLE (LIQUID SERVICE)

N★ – 316 S.S. DISK & NOZZLE (SOUR GAS SERVICE)

B★ – 316 S.S. DISK & NOZZLE (SOUR LIQUID SERVICE)

X – ALL 316 S.S. (OPTIONAL GAS SERVICE)

LX – ALL 316 S.S. (OPTIONAL LIQUID SERVICE)

BX – ALL 316 S.S. (OPTIONAL SOUR LIQUID SERVICE)

NX – ALL 316 S.S. (OPTIONAL SOUR GAS SERVICE)

H | O-RING MATERIAL

1★ – FKM & BUNA-N (STANDARD)

2 – FKM 75 DURO

3 – FKM 90 DURO

4 – BUNA-N 70 DURO

5 – BUNA-N 75 DURO (LOW TEMP)

7 – FFKM

9 – NEOPRENE

A – CHEMRAZ®

C – EPDM 80 DURO

D – EPDM 90 DURO

G – TFE/P

H – SILICONE

J – FLUOROSILICONE

K – HNBR

L – PC BUNA

M – FKM ED

P – FKM 75 DURO (LOW TEMP)

I | TWO-DIGIT "SPECIAL" CODE

(Two-digit special codes assigned by Mercer Valve, if applicable.)

★Standard Materials or Options.

91 -

61

A

K

B

5

C

1

D

T

E

84

F

U

G

1

H

I

A | INLET & OUTLET COMBINATION

(See Dimensions & Weights, below.)

B | API ORIFICE LETTER

K – 2.074 in²

C | INLET BASE & BODY MATERIAL

5★ – CARBON STEEL / WCB CARBON STEEL

7 – 316 STAINLESS STEEL / CF3M STAINLESS STEEL

R – 316 STAINLESS STEEL / LCC CARBON STEEL

D | CAP TYPE

1★ – CLOSED CAP

2 – OPEN LIFT LEVER

3 – CLOSED LIFT LEVER

E | SEAT MATERIAL

V★ – FKM

T★ – PTFE

B – BUNA-N

E – EPDM

N – NEOPRENE

Y – VESPEL®

F – FKM (LOW TEMP)

F | SPRING CODE

(Spring codes assigned by Mercer Valve.)

G | TRIM CODES

U★ – 316 S.S. DISK & NOZZLE (GAS SERVICE)

L★ – 316 S.S. DISK & NOZZLE (LIQUID SERVICE)

N★ – 316 S.S. DISK & NOZZLE (SOUR GAS SERVICE)

B★ – 316 S.S. DISK & NOZZLE (SOUR LIQUID SERVICE)

X – ALL 316 S.S. (OPTIONAL GAS SERVICE)

LX – ALL 316 S.S. (OPTIONAL LIQUID SERVICE)

BX – ALL 316 S.S. (OPTIONAL SOUR LIQUID SERVICE)

NX – ALL 316 S.S. (OPTIONAL SOUR GAS SERVICE)

H | O-RING MATERIAL

1★ – FKM & BUNA-N (STANDARD)

2 – FKM 75 DURO

3 – FKM 90 DURO

4 – BUNA-N 70 DURO

5 – BUNA-N 75 DURO (LOW TEMP)

7 – FFKM

9 – NEOPRENE

A – CHEMRAZ®

C – EPDM 80 DURO

D – EPDM 90 DURO

G – TFE/P

H – SILICONE

J – FLUOROSILICONE

K – HNBR

L – PC BUNA

M – FKM ED

P – FKM 75 DURO (LOW TEMP)

I | TWO-DIGIT "SPECIAL" CODE

(Two-digit special codes assigned by Mercer Valve, if applicable.)

★Standard Materials or Options.

| Inlet and Outlet Code | Inlet and Outlet Size (in) | Pressure Limit 1, 2 (psig) | Dimensions 2

"A" x "B" x "C" (in ± .062) | Approximate Weight 2 (lbs) |

|---|---|---|---|---|

| Inlet and Outlet Code 61★ | Inlet and Outlet Size (in)3" MNPT x 3" FNPT | Pressure Limit 1, 2 (psig)750 | Dimensions 2

"A" x "B" x "C" (in ± .062)5.500 x 4.250 x 13.500 | Approximate Weight 2 (lbs)53 |

1Pressure limit may be subject to system conditions and temperatures.

2Pressure limit, weight, and “C” dimension may vary with sour gas service and other options.

★Standard Materials or Options.

| Inlet and Outlet Code | Inlet and Outlet Size DN (mm) | Pressure Limit 1, 2 (kPa) | Dimensions 2 "A" x "B" x "C" (mm ± 1.6) | Approximate Weight 2 (kg) |

|---|---|---|---|---|

| Inlet and Outlet Code61★ | Inlet and Outlet Size DN (mm)DN 80 (MNPT) x DN 80 (MNPT) | Pressure Limit 1, 2 (kPa)5171 | Dimensions 2 "A" x "B" x "C" (mm ± 1.6)139.7 x 108.0 x 438.2 | Approximate Weight 2 (kg)24.0 |

1Pressure limit may be subject to system conditions and temperatures.

2Pressure limit, weight, and “C” dimension may vary with sour gas service and other options.

★Standard Materials or Options.