9100 Series | Threaded

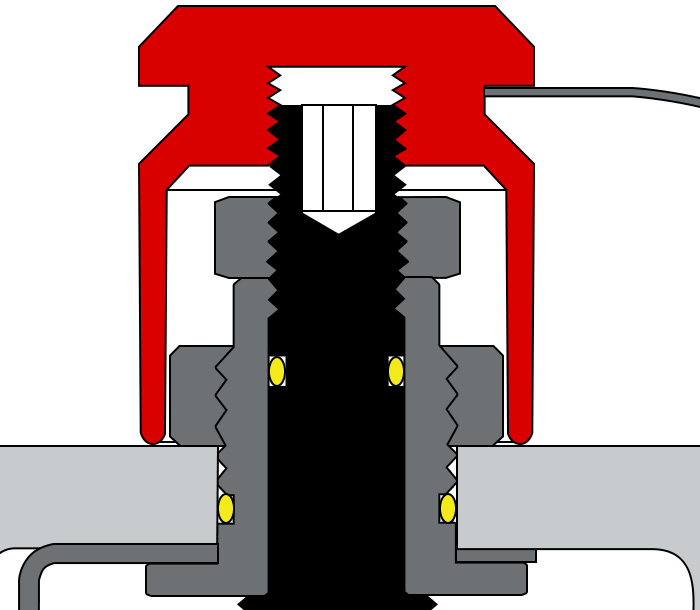

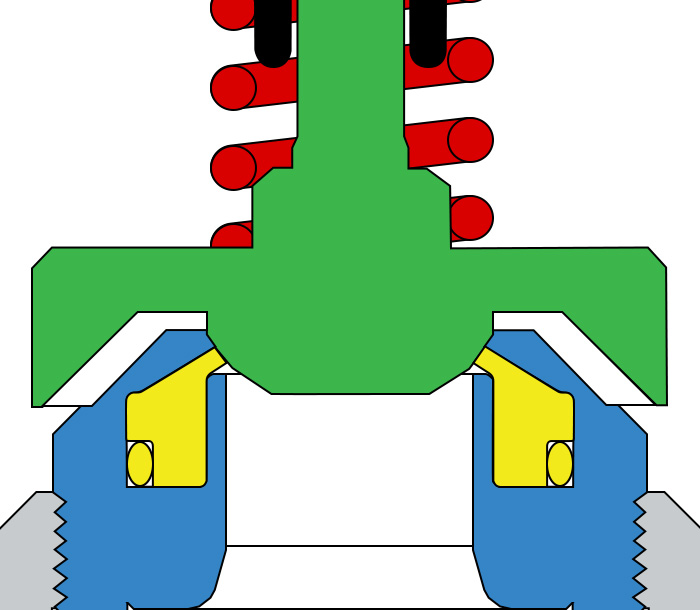

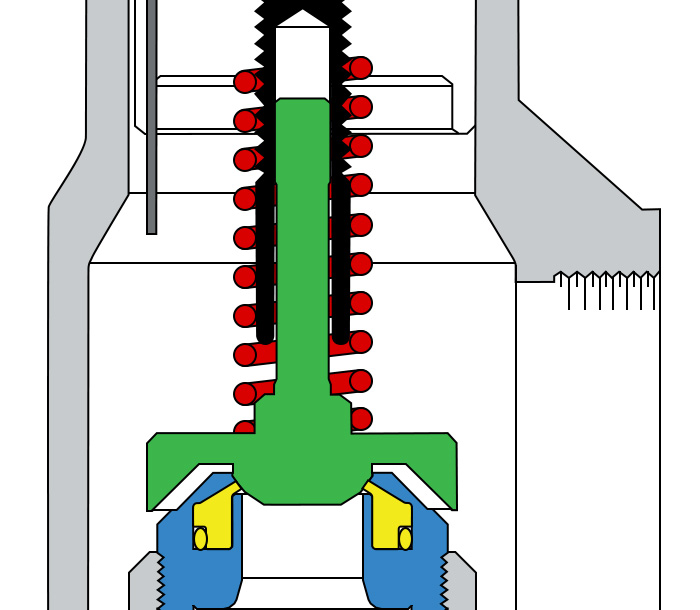

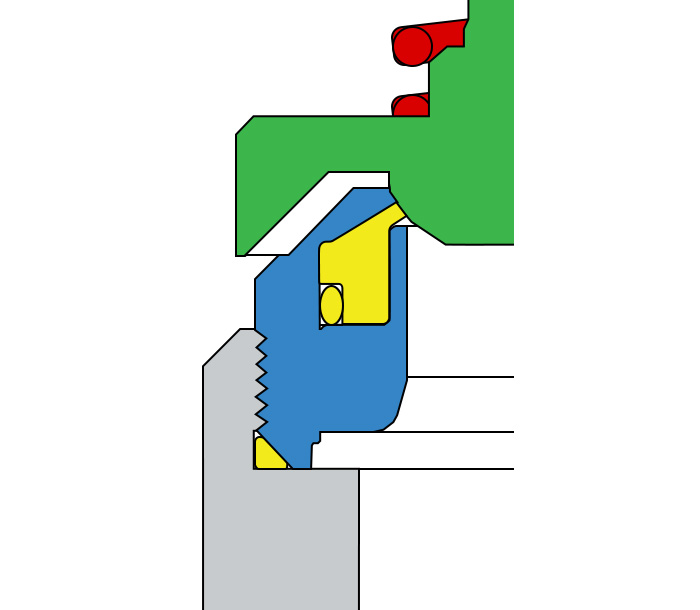

Our 9100 Threaded Series is state of the art when it comes to a soft seat and high flow rate design. It is an industry leader in pressure relief devices with a reputation for safety and reliability, low maintenance, and cost effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures and a field proven tight lip seal. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety.

The 9100 Threaded Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications. This valve is well suited for specialty gases, compressors, separators, gathering lines and anywhere else you need a safe and reliable valve. With a service range of 10 psig to 3500 psig and a wide array of options and applications, our 9100 Threaded Series is a valve that you trust.

9100 Threaded “C” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “D” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “E” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “F” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “G” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “H” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “J” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Threaded “K” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

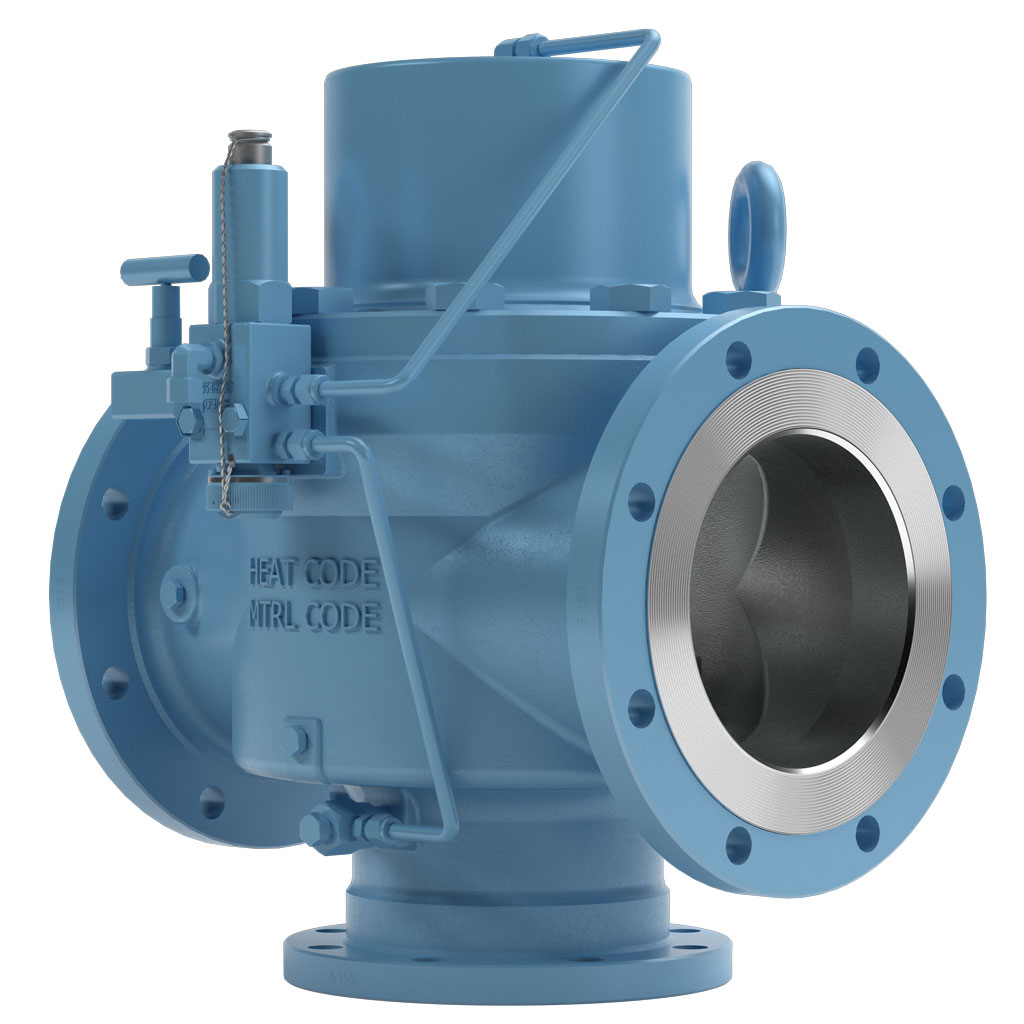

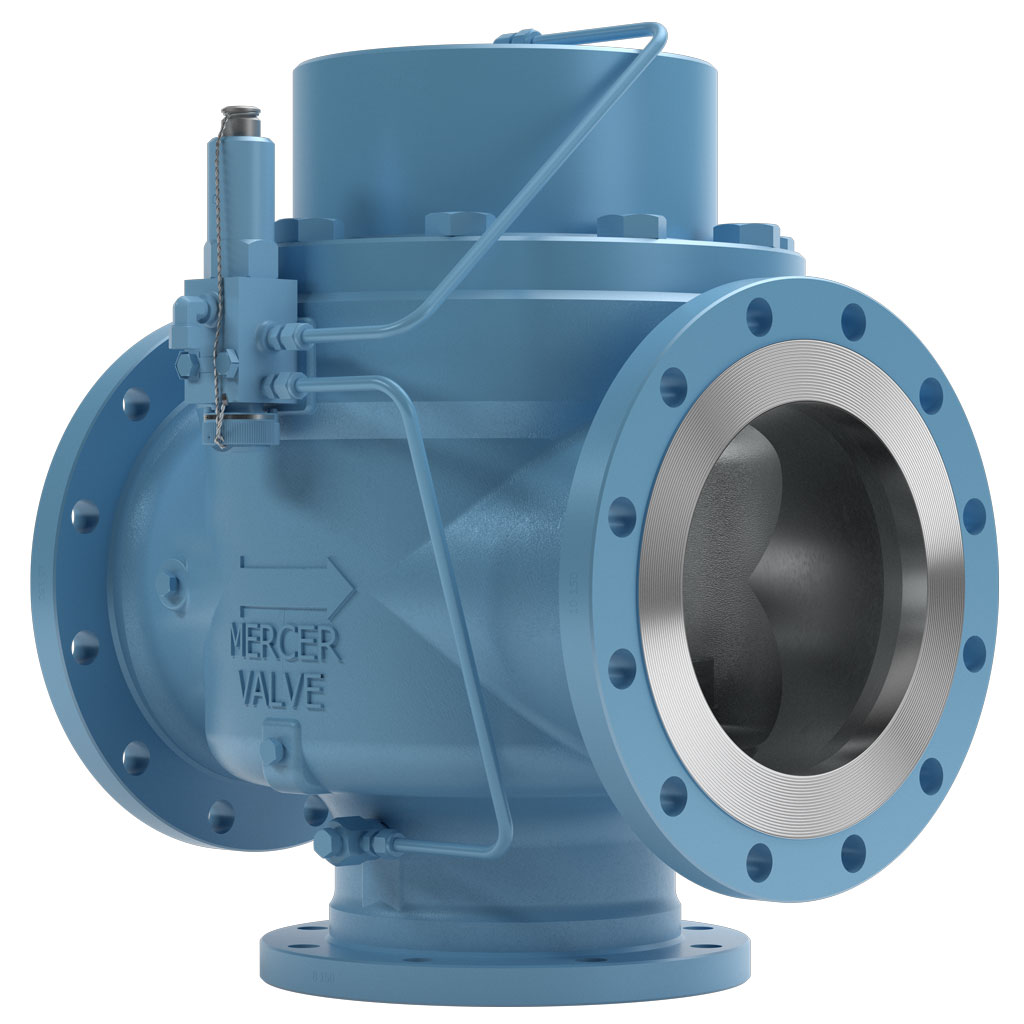

9100 Series | Flanged

Like the 9100 Threaded series, our 9100 Flanged Series is also

state of the art when it comes to a soft seat and high flow rate

design. It is an industry leader in pressure relief devices with a

reputation for safety and reliability, low maintenance, and cost

effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures and a field proven tight lip seal. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety. The 9100 Flanged Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped application for Air/Gas and Liquid service. This valve is well suited for specialty gases, compressors, separators, gathering lines and anywhere else you need a safe and reliable valve. With a service range of 10 psi to 3500 psi and a wide array of options and applications, our 9100 Flanged Series is a valve that you trust.

9100 Flanged “C” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “D” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “E” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “F” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “G” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “H” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “J” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “K” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “L” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “M” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “N” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

9100 Flanged “P” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

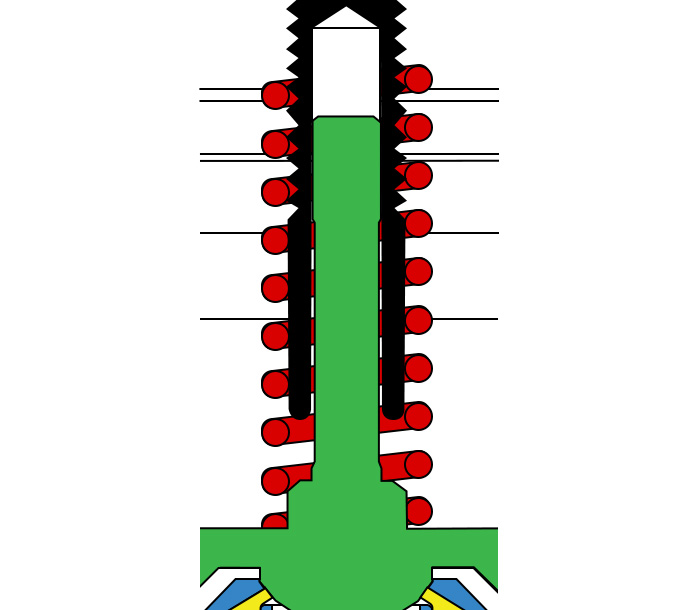

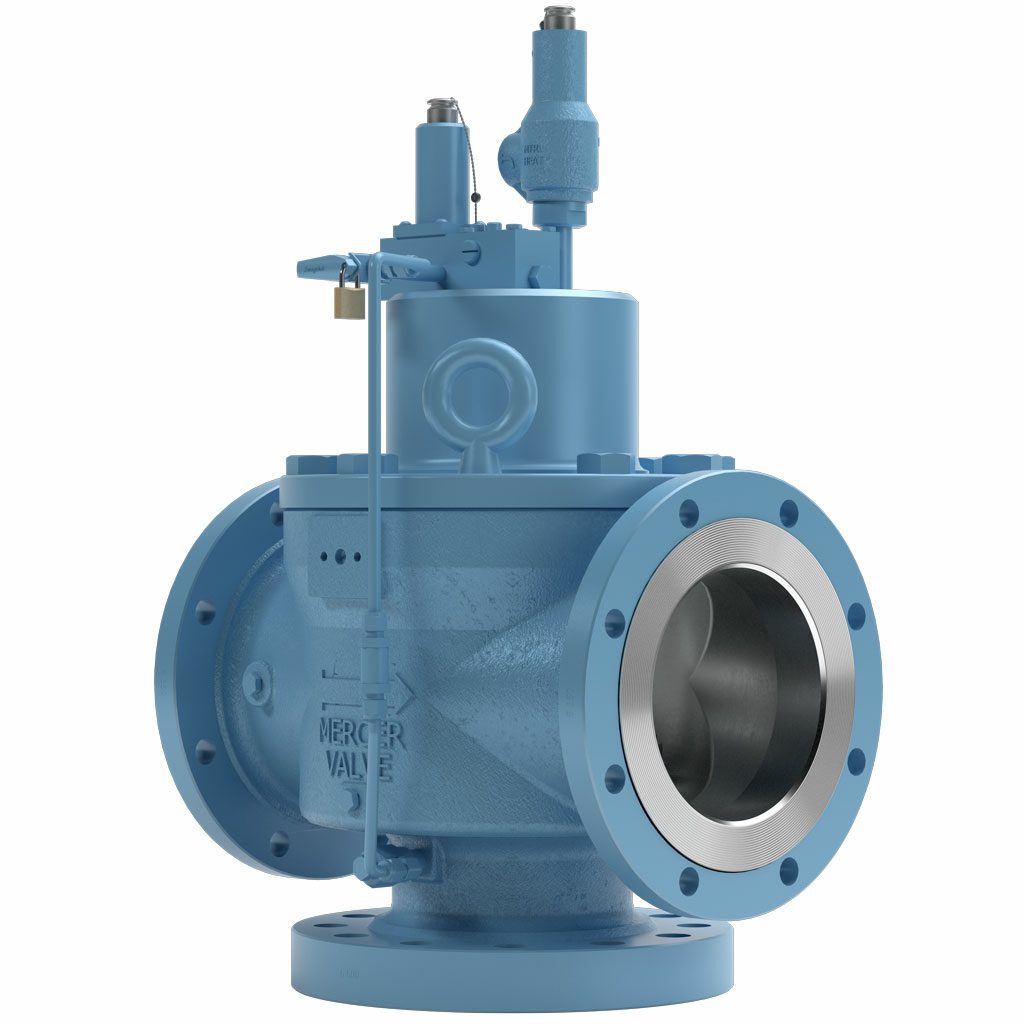

9500 Series | Snap Pilot

Our 9500 Snap Pilot Series is designed to pop open in response to pressure pickup at the inlet of the main valve. Our snap pilots have an adjustable blowdown that alters the set spring deflection once the valve has popped and the greater the deflection, the shorter the blowdown. Our 9500 Snap Pilot is based on proven control design principals, featuring our "Auto Seat Technology"®. The 9500 Snap Pilot Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas service. When you need to regulate system pressures and maintain overall quality, you need a safe and reliable valve. With a service range of 15 psi to 4500 psi and a wide array of options and applications, our 9500 Snap Pilot Series is a valve that you trust.

9500 Snap Pilot “D” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “E” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “F” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “G” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “H” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “J” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “K” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “L” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “M” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “N” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “P” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “Q” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “R” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot “T” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 1-1/2″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 2″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 3″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 4″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 6″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Snap Pilot 8″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Series | Gas Modulating Pilot

Our 9500 Gas Modulating Series is designed to gradually open the main valve in response to system overpressure. Modulating pilots produce far less shock on a system and provide considerable resistance to wear and tear on the main valve components. Our 9500 Gas Modulating Pilot is based on proven control design principals, featuring our "Auto Seat Technology"®. The 9500 Gas Modulating Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas service. You need a safe and reliable valve when it comes to regulating system pressures and maintaining overall quality. With a service range of 15 psi to 4500 psi and a wide array of options and applications, our 9500 Gas Modulating Pilot Series is the valve

you can trust.

9500 Gas Modulating “D” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “E” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “F” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “G” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “H” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “J” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “K” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “L” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “M” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “N” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “P” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “Q” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “R” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating “T” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 1 ½” Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 2″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 3″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 4″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 6″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Gas Modulating 8″ Full Bore

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Series | Liquid Modulating Pilot

Our 9500 Liquid Modulating Series is designed to gradually open the main valve in response to system overpressure. Modulating pilots produce far less shock on a system and provide considerable resistance to wear and tear on the main valve components. Our 9500 Liquid Modulating Pilot is based on proven control design principals, featuring our "Auto Seat Technology"®. The 9500 Liquid Modulating Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Liquid service. When you need to regulate system pressures and maintain overall quality, you need a safe and reliable valve. With a service range of 15 psi to 1480 psi and a wide array of options and applications, our 9500 Liquid Modulating Pilot Series is a valve that you trust.

9500 Liquid Modulating “F” Orifice

Manufactured to ASME requirements for Liquid service.

Learn More >

9500 Liquid Modulating “H” Orifice

Manufactured to ASME requirements for Liquid service.

Learn More >

9500 Liquid Modulating “J” Orifice

Manufactured to ASME requirements for Liquid service.

Learn More >

9500 Liquid Modulating “L” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Liquid Modulating “M” Orifice

Manufactured to ASME requirements for Liquid service.

Learn More >

9500 Liquid Modulating “P” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Liquid Modulating “R” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9500 Liquid Modulating “T” Orifice

Manufactured to ASME requirements for Liquid service.

Learn More >

8100 Series

Our 8100 Series is state of the art when it comes to a soft seat and high flow rate design. It is an industry leader in pressure relief devices with a reputation for safety and reliability, low maintenance, and cost effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures and a field proven tight lip seal. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety. The 8100 Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas and Liquid service. The 8100 Series is designed for applications ranging from 15 psi up to 2000 psi. With its non-rising stem and smaller frame this valve is perfect for all those tight spaces and anywhere else you need a safe and reliable valve.

8100 “E” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

8100 “G” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid service.

Learn More >

8500 Series

Our 8500 Series is state of the art when it comes to a soft seat and high flow rate design. It is an industry leader in pressure relief devices with a reputation for safety and reliability, low maintenance, and cost effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures and a field proven tight lip seal. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety. The 8500 Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas service. The 8500 Series is designed for applications ranging from 15 psi up to 1650 psi. With its non-rising stem and smaller frame this valve is perfect for all those tight spaces and anywhere else you need a safe and reliable valve.

8500 “E” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

9100 Series Model 20

Our 9100 Model 20 Series is state of the art when it comes to a soft seat and high flow rate design. It is an industry leader in pressure relief devices with a reputation for safety and reliability, low maintenance, and cost effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures and a field proven tight lip seal. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety. The 9100 Model 20 Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas and Liquid service. This high pressure safety relief valve is designed for CNG and other high pressure applications from 3000 psi up to 8700 psi. When safety is on the line, this is a reliable valve you can trust.

9100 Model 20 “C” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid Service.

Learn More >

9100 Model 20 “D” Orifice

Manufactured to ASME requirements for Air/Gas and Liquid Service.

Learn More >

1400 Series

Our 1400 Series is state of the art when it comes to a soft seat and high flow rate design. It is an industry leader in pressure relief devices with a reputation for safety and reliability, low maintenance, and cost effectiveness. Our soft seat and fully guided disk design outlasts the competition and produces a valve that has consistent set pressures. A tighter seal reduces leaks and limits product loss which leads to increased productivity and safety. The 1400 Series valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section XIII UV stamped applications for Air/Gas service. The 1400 Series is designed for applications ranging from 150 psi up to 6000 psi. With its non-rising stem and smaller frame this valve is perfect for all those tight spaces and anywhere else you need a safe and reliable valve.

1400 “B” Orifice

Manufactured to ASME requirements for Air/Gas service.

Learn More >

Additional Products

Weather Caps

The weather cap is a PVC valve cover that is the best insurance against valve deterioration caused b...

Learn More >

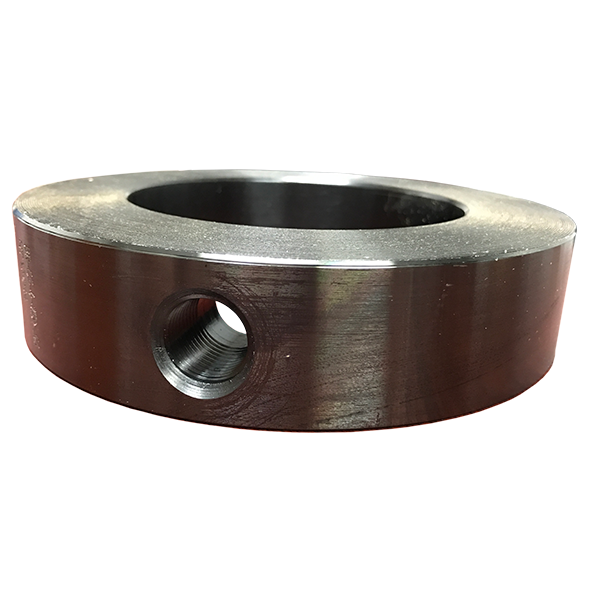

Bleed Rings

Top-quality bleed rings made by LR Specialty Metals, Inc.

Learn More >