About Mercer Valve

our mission

Mercer Valve is dedicated to providing the highest quality pressure relief valves and services at a competitive price so our customers can be confident in the safety and reliability of our work. We seek innovative solutions while meeting industry standards. Products or services, we will continue to strive for customer satisfaction and exemplary service.

safety & reliability

A culture of safety saves lives, decreases cost of ownership, increases revenue, and allows more people to go home to their families. That’s why you can rely on our safe practices in our employee training, manufacturing processes, and all services we provide. When you choose Mercer Valve, you’re choosing a safe and reliable partner.

quality & innovation

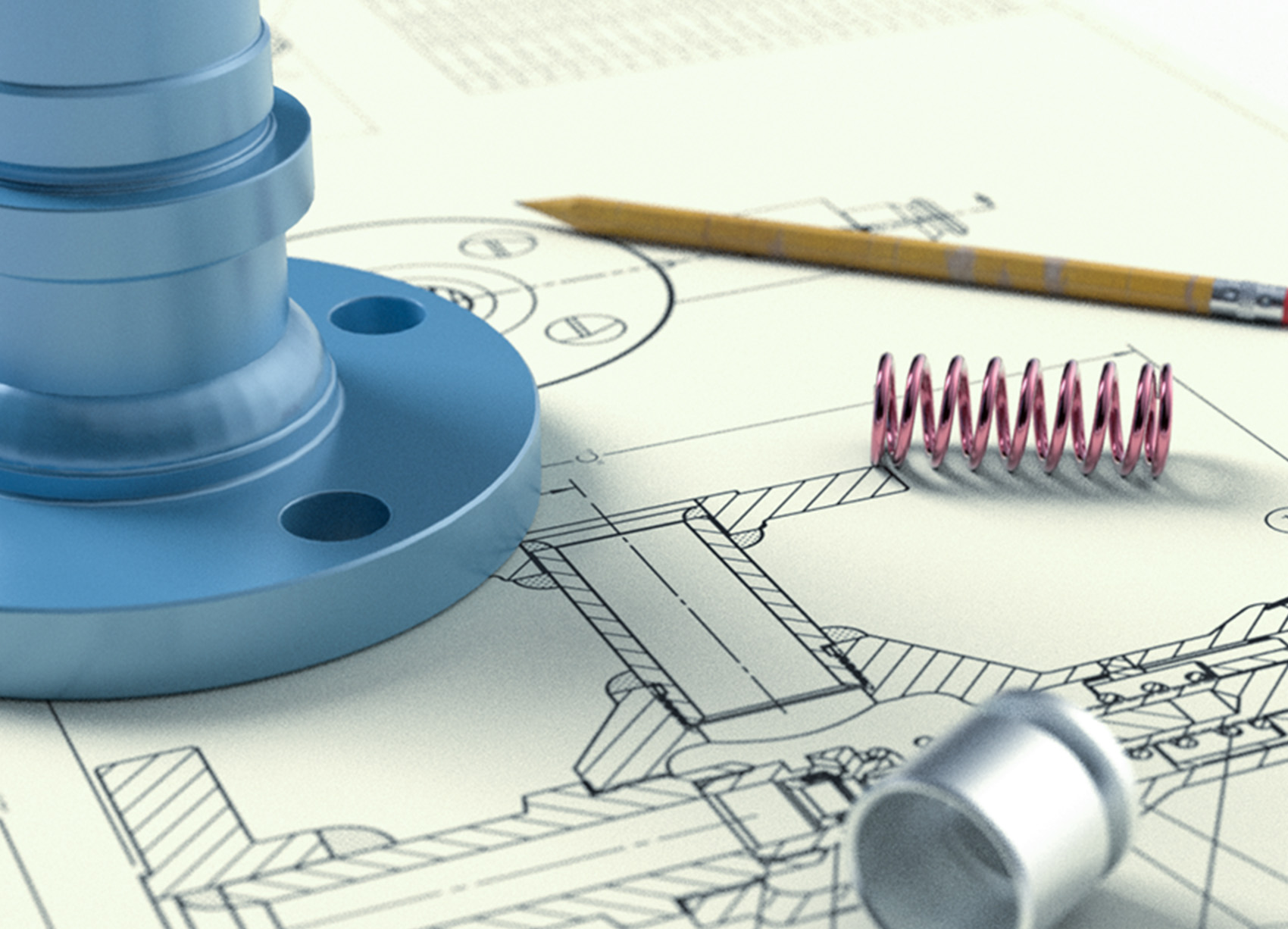

Innovation guides our demand for quality outputs. We are adaptable and capable of sustained innovation that pushes us and make us a viable partner for our customers. Our persistence, driven results, and our improvement strategies help us deliver our high-quality services and products that our customers have come to depend on.

Family First

Wesley Taylor started Mercer Valve with the foundation of family. This family business model has cultivated our diverse community of employees and customers alike. Our family values evolved into a people-oriented business and when you work with us, you get a company that puts respect, trust, and integrity into everything we do.

it starts with safety

Mercer Valve produces the finest pressure relief valves for all industries. Where safety is our top priority, our best-in-class valve manufacturing and technology will safeguard the people, equipment and environments that are essential to business success. To install Mercer Valve’s pressure relief valves is to further ensure that your productivity continues and your employees return home safely to their families.

a class of its own

Our “Auto Seat Technology”® uses low rated springs and a non-rising stem to increase seat life, reduce repairs and achieve a consistent set pressure. This potentially life-saving technology sets Mercer Valve’s products apart from other pressure relief valves.

Check out our Products!

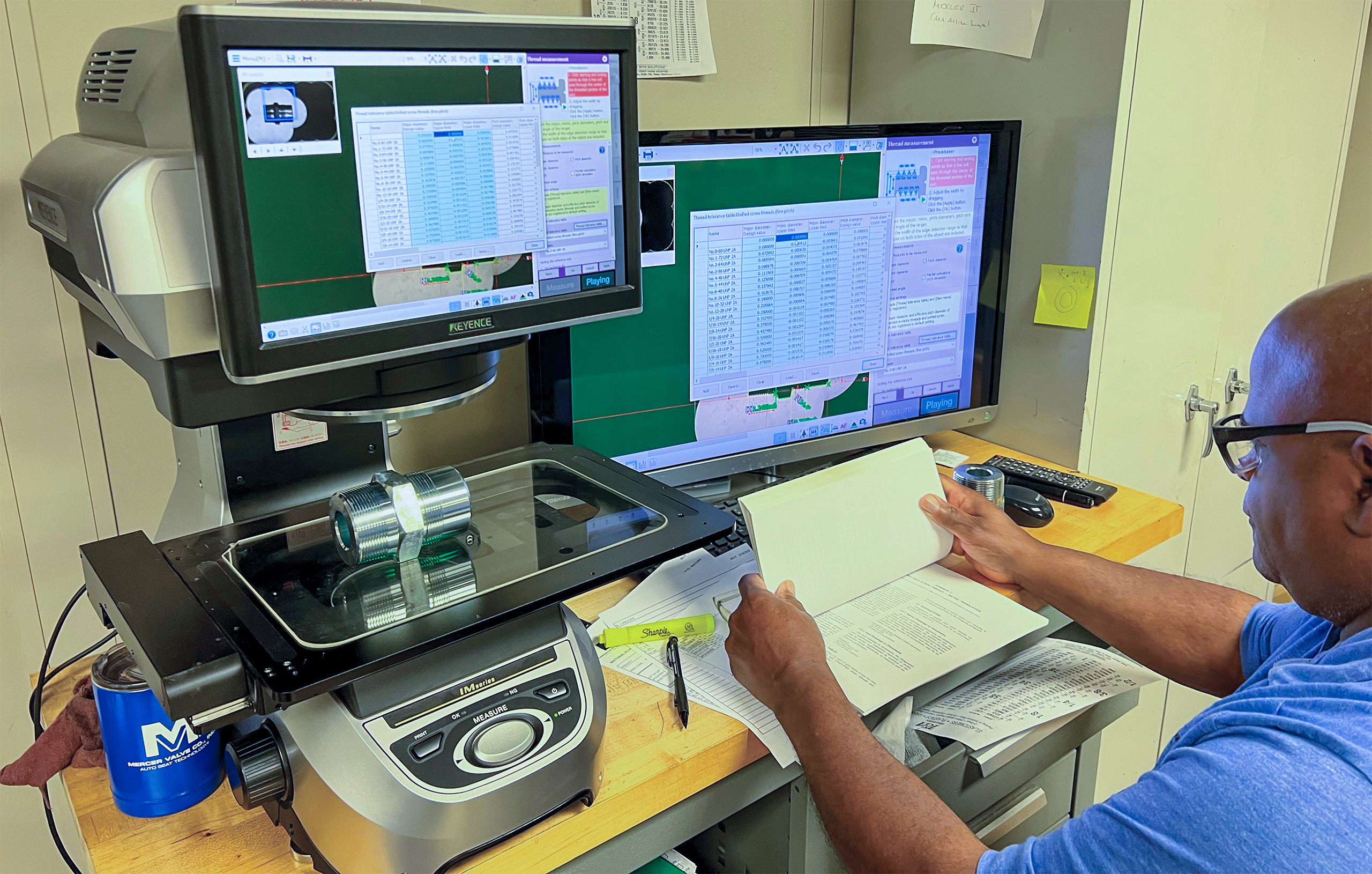

people and products

of the highest quality

Whether it’s on our manufacturing floors or out on-site doing service and repairs, safety is a priority we keep at all times. We champion it, reward and train for it relentlessly. Doing so keeps our workforce vigilant, connected and laser-focused. In addition to frequent safety training, we participate in diversity, equity and inclusion training to ensure we maintain a work environment where everyone feels included and valued.

trade shows and webinars

At Mercer Valve, we are always looking for ways to connect with our customers. You can find us at many different trade shows around the United States, Australia and Canada.

Did you know we also offer a variety of online resources, including live webinars for free? If you’re interested check out our LinkedIn page or Contact us for more information.

quality policy

Mercer Valve Co., Inc® is committed to safely providing the highest quality pressure relief valve featuring our “Auto Seat Technology”® at a competitive price, delivered on time, and serviced by our trained professionals. We continue to improve our products and services, while meeting industry standards to satisfy our customer’s expectations.